Focusing on the innovation ability of industrial digital intelligence, ADI creates a new shortcut for the high-quality development of intelligent manufacturing.

As the global manufacturing industry faces increasingly complex challenges and opportunities, intelligent manufacturing technology is becoming the core driving force of industrial change. With the rapid development of cutting-edge technologies such as Internet of Things (IoT), artificial intelligence (AI) and edge computing, the manufacturing industry is welcoming a wave of digital transformation. This transformation not only improves production efficiency and product quality, but also brings unprecedented flexibility and competitive advantage to enterprises. By integrating advanced sensing technology, data analysis and intelligent decision-making, intelligent manufacturing is gradually realizing a more efficient and sustainable production mode, pushing the global manufacturing industry to a new height.

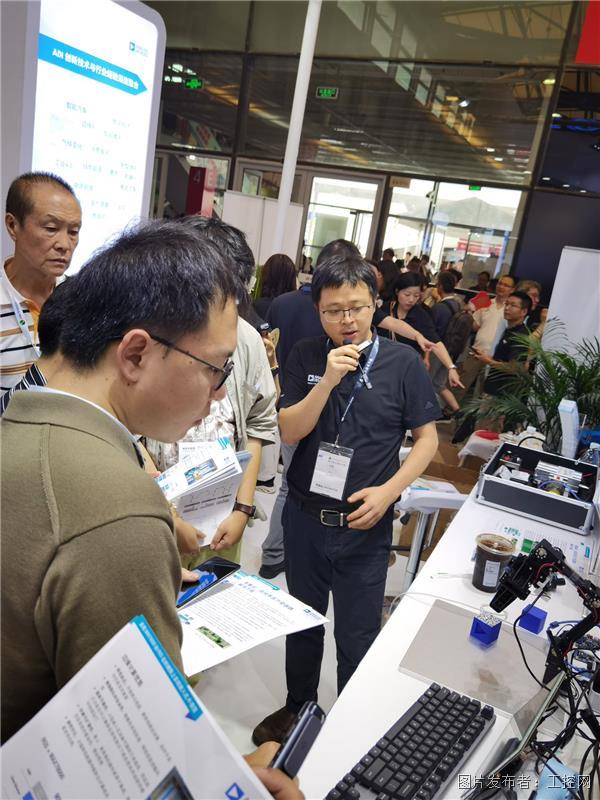

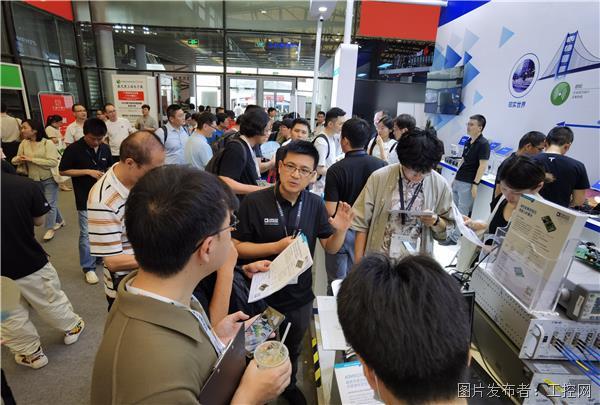

At the recent Shanghai Electronics Show in Munich, the industrial control network and other media interviewed industrial experts from ADI, namely Huang Qingyi, senior marketing manager of power supply business in Asia-Pacific region of ADI, Jiang Haitao, senior marketing manager of instrument division of ADI, and Zhu Zhen, marketing manager of industrial automation industry of ADI, and discussed the frontier applications of Internet of Things, intelligent sensing technology and artificial intelligence in the industrial field together. They not only shared ADI's latest technological innovations and solutions, but also showed how these technologies can promote intelligent manufacturing to a more efficient and sustainable development path.

The deep integration of industrial edge computing and intelligent sensing creates a new level of intelligent manufacturing.

With the deepening of Industry 4.0 and intelligent manufacturing, the amount of industrial data has exploded, and the demand for edge computing and intelligent sensing technology has become more and more urgent. The development of these technologies not only improves the real-time response ability of the production line, but also lays the foundation for the manufacturing industry to realize a more efficient and flexible production management model.

Zhu Zhen showed the cutting-edge technologies and application cases of ADI in industrial intelligence. He introduced the application of ADE9430 power quality analyzer and MAX series pressure sensors in detail, and pointed out: "These technologies not only improve the data processing ability and accuracy, but also support the demand of real-time response and data analysis in factories." Zhu Zhen introduced that ADE9430 power quality analyzer integrates complex signal chain and algorithm library, which greatly simplifies the complexity of power quality monitoring, enables it to be easily integrated into small electric meters, and provides efficient and accurate power quality monitoring solutions for new energy vehicles and precision equipment.

The industrial control network believes that the application of ADE9430 power quality analyzer greatly simplifies the complexity of industrial power quality monitoring and provides accurate energy analysis and monitoring solutions for factories. This technology not only helps to improve the energy efficiency and stability of industrial equipment, but also supports the factory to achieve a more efficient and sustainable production management model, which provides important technical support for the transformation of industry to intelligent manufacturing.

In addition, Zhu Zhen also introduced the innovative solution of MAX78000 in industrial edge AI application. MAX78000 integrates Cortex-M4 and RISC-V processors, supports complex algorithms and real-time data processing, and shows strong application potential especially in industrial automation and robot operating systems. Its hardware acceleration unit supports neural convolution network, which enables it to efficiently process parallel computing, thus realizing the edge computing ability of AI reasoning and data processing locally, greatly reducing data transmission delay and bandwidth requirements, improving data security and product real-time, and injecting new power and possibility into the development of industrial intelligence.

Efficient energy management and precision testing are the cornerstones to realize the sustainable development of digital intelligence.

In the process of global manufacturing moving towards intelligence and digitalization, energy efficiency and precision testing technology have become the key factors to enhance the competitiveness of enterprises. Efficient energy management can not only significantly reduce production costs and environmental impact, but also be an important path to achieve sustainable development. Precise testing and measuring technology provides a solid foundation for product quality and R&D innovation, and ensures the efficiency and reliability of the manufacturing process.

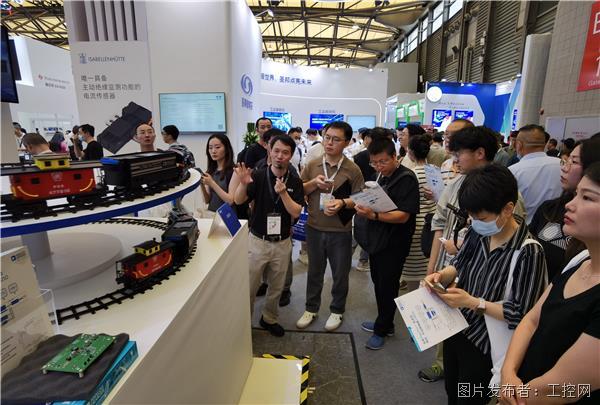

Starting from two leading power management products of ADI, LT8210 and Silent Switcher 3, Huang Qingyi explained their importance in improving energy conversion efficiency and reducing circuit noise. He said: "LT8210' s straight-through function can directly connect the input to the output within the voltage range set by the user, thus reducing the switching loss and improving the conversion efficiency by nearly 100%." Huang Qingyi also shared the application of LT8210 in the urban train model project. By comparing the train models with different designs, he clearly demonstrated how the through function can prolong the running time of the energy storage system.

It can be seen that in intelligent manufacturing, efficient energy management is not only related to cost saving, but also the cornerstone of sustainable development. ADI's LT8210 greatly improves the energy conversion efficiency through the straight-through technology, which is in line with the trend of green manufacturing. For example, the urban train model project shows its advantages in prolonging the running time of the energy storage system.

Of course, whether it is the sustainable development of industrial digital intelligence or the high-quality development of manufacturing industry, it is inseparable from the collection and mining of industrial bottom data. In this regard, Jiang Haitao introduced in detail the high-precision test solutions of ADI's instrumentation department, including ADMX3001, 8-port VNA and high-performance precision impedance measurement and analysis module. He stressed: "These technologies support closed-loop control and accurate data acquisition through high-speed and high-precision testing instruments, which provide key support for manufacturing industry in product development and quality control." Among them, Jiang Haitao first introduced ADMX3001. He said that this solution adopted the latest amplifier products and 24-bit SAR ADC, and realized closed-loop control through high-speed and high-precision DAC, especially digital loop control, which helped solve the ringing and accuracy problems that traditional analog loops could not cope with.

In addition, Jiang Haitao also made a detailed analysis of the ADMX2001 high-performance precision impedance measurement and analysis module and the ADMX1002/ADMX1001 high-precision low-distortion signal source. He demonstrated the performance comparison test of these solutions in the laboratory environment, and emphasized the miniaturization and easy integration advantages of these products. He said: "These small boards provide standard API functions through SPI interface, and customers can directly integrate into their own devices, greatly shortening the product development cycle and cost."

Through the observation of the industrial control network, ADI has been committed to providing customers with one-stop software and hardware solutions to help customers shorten the time to market and enhance the market competitiveness of products. At the same time, ADI also combines existing solutions, such as energy management system, high-quality and high-precision testing requirements, which can be customized according to customer needs and meet the specific requirements of different industrial application scenarios.